Modular Learning Cabin Professional Soundproof Video Conferencing Cabin

Handle: Stainless steel handle/Lockable handle

cold-rolled steel plates:0.8mm/1.2mm high-quality cold-rolled steel plates

Wheel: Steel universal wheel, free steering without pressure, beside the configuration of a steel foot cup to prevent the sound insulation room in static displacement

Lighting system: LED lighting with adjustable 3000-4000-6000K natural light color temperature

Cabin configuration: Multi-functional socket(Double five-hole socket +USB+Type-C)

Ventilation system: Dual circulation fresh air system with top intake and bottom exhaust. The temperature difference between the cabin and the external space environment does not exceed 2 degrees Celsius

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

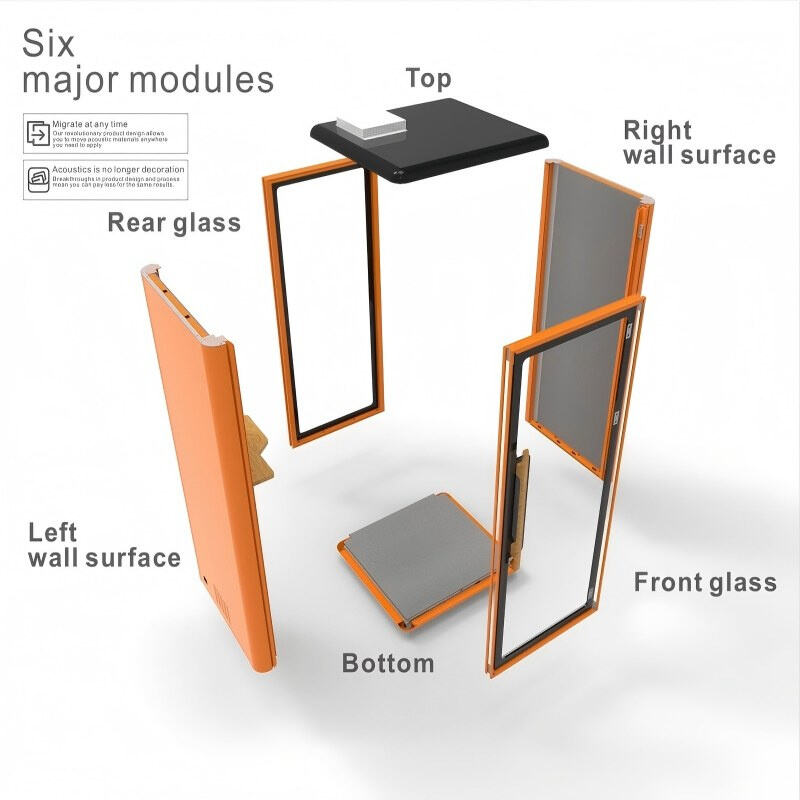

The modular six-component design enables industry-leading 45-minute installation, significantly reducing deployment time and labor costs compared to conventional construction methods. This design philosophy represents a decisive break from legacy approaches to creating dedicated acoustic spaces. By rationalizing the entire structure into six pre-engineered, precision-manufactured modules, the product transforms a complex architectural task into a rapid, repeatable assembly procedure. Each major component—roof, floor, front door, rear wall, and two side walls—arrives as a fully integrated unit with pre-installed hardware, seals, and wiring. This eliminates the hundreds of individual steps, specialized tools, and skilled tradespeople required for traditional drywall construction or complex panelized systems. The on-site process is reduced to a logical sequence of positioning, aligning, and securing these large modules. The dramatic compression of the installation timeline to a mere 45-minute installation directly translates to significantly reduced deployment time, minimizing operational disruption and allowing for immediate use. Concurrently, the drastic reduction in on-site labor hours and complexity leads to a substantial decrease in labor costs, delivering a compelling total cost of ownership and a rapid return on investment that conventional methods cannot match.

Its structural integrity derives from the synergistic combination of 6063-T5 aluminum alloy and 1.2mm cold-rolled steel, protected by premium electrostatic powder coating that exceeds standard adhesion requirements. The longevity and day-to-day resilience of the enclosure are rooted in this hybrid material strategy. The primary exoskeleton is formed from 6063-T5 aluminum alloy, a material chosen for its exceptional strength-to-weight ratio and inherent corrosion resistance. The "T5" temper indicates it has been solution heat-treated and artificially aged, optimizing its mechanical properties for structural applications. This aluminum framework provides a rigid, lightweight, and dimensionally stable backbone. For critical load-bearing junctions and the exterior cladding, the design incorporates 1.2mm cold-rolled steel. The cold-rolling process increases the steel's yield strength and surface hardness, making it exceptionally resistant to impact and deformation. This synergistic combination allows each material to perform optimally: the aluminum ensures overall lightness and stability, while the steel provides localized, high-tensile strength where it is most needed. This robust metal structure is then finished with a premium electrostatic powder coating. This process involves applying a dry polymer powder electrostatically, which is then heat-cured into a uniform, durable film. The quality of this coating is such that it exceeds standard adhesion requirements, verified through rigorous testing like cross-hatch and impact tests. This ensures the finish will not chip, flake, or peel over time, providing long-term protection against scratches, corrosion, and UV degradation, thereby preserving both the aesthetics and the integrity of the underlying metals.

The acoustic system represents a sophisticated engineering achievement, utilizing a multi-layer approach to achieve 32±3 dB sound insulation – a level typically associated with permanent construction. The core function of the enclosure is realized through a meticulously calibrated, physics-based design. Achieving a 32±3 dB sound insulation rating (a high Sound Transmission Class, or STC) is a significant benchmark, indicating a barrier substantial enough to render loud speech unintelligible and dramatically reduce most ambient office or facility noise. This performance is typically associated with permanent construction, such as well-built interior walls, yet here it is accomplished in a demountable, modular form factor. This is the result of a sophisticated engineering achievement that employs a multi-layer approach. The system does not rely on a single magic material but on a sequence of layers, each addressing a different aspect of sound transmission: absorption, damping, mass, and sealing.

This is accomplished through carefully selected materials including E1 grade sound-absorbing boards, specialized insulation fills, and complete EVA perimeter sealing, all meeting stringent requirements for safety, durability, and environmental responsibility. The acoustic assembly is a composite of purpose-engineered components. The interior surface features E1 grade sound-absorbing boards. The E1 classification is the highest European standard for formaldehyde emissions, certifying that these panels contribute to superior indoor air quality while effectively absorbing mid and high-frequency sound waves to control internal reverberation. Behind these boards, the wall cavity is packed with specialized insulation fills—typically dense, non-woven materials like cotton or felt blends. These fills provide broadband sound absorption, converting acoustic energy into minimal heat, and act as a damping layer to disrupt vibrational energy transfer. The most critical element for achieving the high STC rating is the complete EVA perimeter sealing. Soft, compressible Ethylene-Vinyl Acetate (EVA) gaskets are installed along every single seam, panel joint, and door perimeter. When compressed during assembly, they form a continuous, airtight seal that eliminates sound leakage paths (flanking), which are the primary weakness of many acoustic products. Crucially, all meeting stringent requirements for safety, durability, and environmental responsibility. These materials are inherently flame-retardant, zero-VOC (Volatile Organic Compound), moisture-resistant, and chemically stable, ensuring a safe, healthy, and durable acoustic environment.

The 5+(1.14pvd)+5mm laminated safety glass provides enhanced protection and noise reduction while maintaining transparency. The glazing solution is engineered for multiple performance criteria. The specification 5+(1.14pvd)+5mm denotes a laminated glass panel: two 5mm sheets of glass are permanently bonded to a 1.14mm thick polyvinyl butyral (PVB) interlayer. This construction offers enhanced protection; if impacted, the glass may crack, but the PVB layer holds the fragments in place, preventing them from scattering and causing injury, meeting stringent safety glazing codes. Acoustically, the viscous PVB layer acts as a constrained damping layer, and the composite mass of the two glass panes provides superior sound blocking compared to single-pane glass of equivalent thickness, contributing significantly to noise reduction. All this is achieved while maintaining excellent optical clarity and transparency, preserving an open visual connection to the outside environment and preventing any sense of claustrophobia.

Climate management is handled intelligently through a dual-circulation ventilation system that ensures continuous fresh air exchange without pressure imbalances or significant temperature fluctuations (≤2°C difference). Maintaining comfort in a sealed, occupied space is a critical engineering challenge. The solution is an intelligently designed dual-circulation ventilation system. It employs two independent, low-noise fans operating in a balanced manner: one dedicated to introducing fresh air, and another to exhausting stale air at an equal rate. This balance is key; it ensures continuous fresh air exchange to replenish oxygen and remove CO2, preventing stuffiness, without pressure imbalances. Neutral internal pressure is vital—it prevents doors from being difficult to open or close (a sign of negative pressure) and stops air from being forced out through acoustic seals (a sign of positive pressure), which would compromise sound insulation. Furthermore, the system's design, combined with the enclosure's insulation, limits significant temperature fluctuations to within a ≤2°C difference from the external environment. This prevents heat buildup from occupants, lighting, and equipment, ensuring thermal comfort is maintained effortlessly.

Visual comfort is prioritized through 4500K natural light spectrum LEDs that reduce eye strain during extended use. Recognizing that lighting quality directly impacts well-being and productivity, the illumination system is carefully specified. It utilizes LEDs with a 4500K natural light spectrum. This correlated color temperature emits a neutral white light, closely resembling daylight. This spectrum minimizes the proportion of high-energy blue light found in cooler (e.g., 6000K+) LEDs, which is linked to digital eye strain and circadian rhythm disruption. By providing a balanced, comfortable light, it actively works to reduce eye strain during extended use of computers, reading, or detailed work.

Together, these features create a complete, high-performance environment that supports productivity, focus, and well-being. In synthesis, the product is more than the sum of its parts. The rapid deployment, robust construction, exceptional acoustics, safe glazing, intelligent climate control, and ergonomic lighting are not isolated features but interconnected elements of a unified system. This integration creates a complete, high-performance environment. By delivering effective sound isolation, it directly supports productivity and focus by minimizing auditory distractions. By ensuring fresh air, thermal stability, visual comfort, and material safety, it fundamentally supports… well-being, making it a sustainable solution for long-term use. This holistic approach delivers a turnkey sanctuary designed for the cognitive and physical demands of modern work and study.

Specifications

| Place of Origin | Guangdong,China |

| Brand Name | cleader |

| Model Number | CA-X002P |

| Product Dimensions | 1250W*990D*2300H |

| Number of fans | 1 |

| Shape | Rectangle |

| Board material | Medium-density fiberboard |

| Framework materials | High-strength aluminum profile |

| soundproof tempered glass | 8mm transparent 3C-certified safety and soundproof tempered glass/5+ (1.14pvd) +5mm transparent 3c certified safety, laminated soundproof tempered glass |

| Handle | Stainless steel handle/Lockable handle |

| cold-rolled steel plates | 0.8mm/1.2mm high-quality cold-rolled steel plates |

| Wheel | Steel universal wheel, free steering without pressure, beside the configuration of a steel foot cup to prevent the sound insulation room in static displacement |

| Lighting system | LED lighting with adjustable 3000-4000-6000K natural light color temperature |

| Cabin configuration | Multi-functional socket(Double five-hole socket +USB+Type-C) |

| Ventilation system | Dual circulation fresh air system with top intake and bottom exhaust. The temperature difference between the cabin and the external space environment does not exceed 2 degrees Celsius |

Applications

Advantages

Engineered for superior value, this solution delivers unmatched efficiency with its 45-minute modular installation. It offers long-term durability through its hybrid aluminum-steel construction and premium finish. Occupants benefit from a quiet, 32 dB-rated environment created by a non-toxic acoustic package, enhanced safety and soundproofing from laminated glass, consistent comfort via intelligent climate control (ΔT≤2°C), and reduced eye strain from health-optimized 4500K lighting—all in one integrated package.

FAQ

Q1: What is the sound insulation rating of your phone booths?

A: Our silent cabin is equipped with a multi-layer sound insulation system, which can achieve a sound insulation effect of 28±3 and 32±3 decibels.Please refer to the product description for details.

Q2: How long does installation take?

A: Thanks to the modular design with only six main components, installation typically takes about 45 minutes on-site.We offer installation videos.

Q3: Do you offer different sizes for single, double, or multiple-person booths?

A: Yes, we offer various sizes of silent cabins, including single and double, and the size can be customized according to your needs. For more requirements, please contact us.

Q4: How is ventilation handled inside the booth?

A: Each booth features a dual-circulation fresh air system with top intake and bottom exhaust, maintaining a temperature difference of less than 2°C from the outside environment.

Q5: Can I add additional features like monitor mounts or extra power outlets?

A: Absolutely.For more requirements, please contact us.

Q6: What is the lead time for standard and customized orders?

A: Standard models ship within 20-25 business days.For more requirements, please contact us.

Q7: What is the payment method?

A: We accept T/T. For more requirements, please contact us.

Q8: Do you provide product samples? What about the cost?

A:Material samples can be provided. The shipping cost for the samples is at your own expense. For more requirements, please contact us.