School Theater Seat Hall Auditorium Chair with Writing Pad Lecture Chair

Place of Origin: Guangdong,China

Brand Name: Cleader

Sponge: Uses PU shaped sponge

Backrest outer panel: Uses high-quality multi-layer molded paint back panel

Fabric: Uses high-quality linen/wool fabric finish

Armrests: Use aluminum alloy armrests

Armrest cover: Uses natural wood color semi-open paint

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

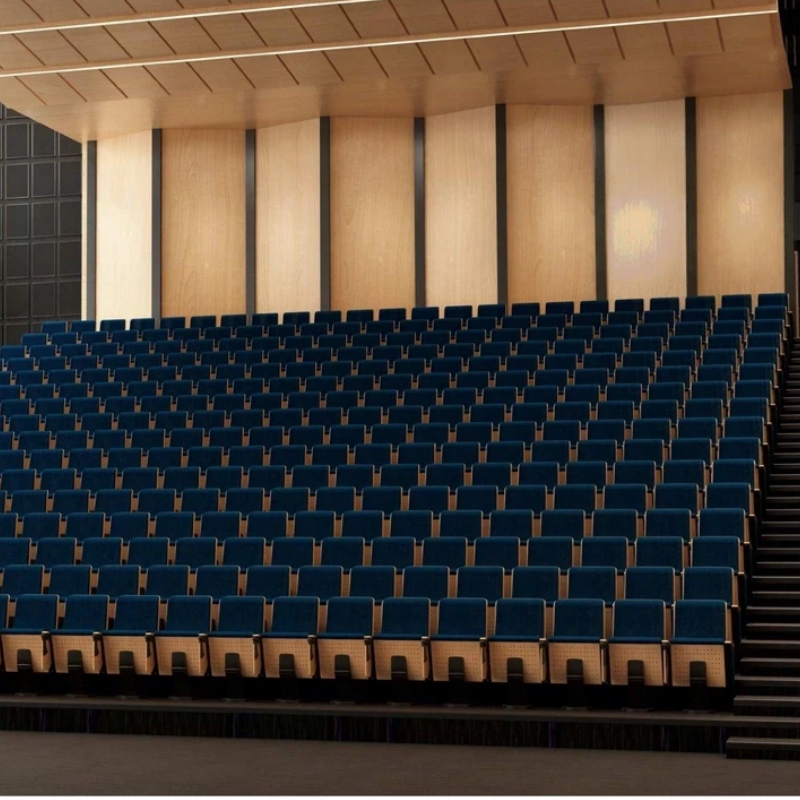

In the realm of institutional and cultural environments where collective experiences unfold through extended periods of seated engagement, the Cleader Auditorium Seating System emerges as a sophisticated synthesis of ergonomic science, material engineering, and architectural design. This meticulously crafted seating solution represents the convergence of physiological comfort research, acoustic optimization principles, and spatial efficiency considerations, offering a comprehensive seating platform that actively supports both individual comfort and collective experience in communal gathering spaces. Manufactured with precision in Guangdong, China—a region celebrated for its manufacturing innovation and quality standards—this auditorium chair transcends conventional public seating through its intelligent integration of supportive comfort, durable construction, and aesthetic refinement that understands how seating systems influence audience engagement, event duration tolerance, and spatial atmosphere in collective environments.

Comfort Engineering: Advanced Support Systems

The chair's foundational comfort originates from its PU molded spongecushioning system that provides scientifically calibrated support through graduated density zones. This advanced polyurethane formulation undergoes specialized molding processes that create cellular structures optimized for pressure distribution across prolonged seating periods. The sponge demonstrates exceptional resilience retention, maintaining its supportive characteristics through thousands of compression cycles without permanent deformation or comfort degradation. The graduated density design places firmer support in lumbar regions where structural reinforcement is most critical, while providing more yielding comfort in contact areas requiring pressure relief. This intelligent comfort engineering recognizes that effective auditorium seating must balance immediate comfort with sustained support through events of varying duration, creating seating experiences that enhance rather than distract from the content being presented.

Structural Integrity: Layered Construction Excellence

Supporting the comfort systems is a high-quality multi-layer molded paint back panel that combines structural robustness with refined aesthetics. This engineered panel employs composite layering techniques where each stratum serves specific functional purposes—structural reinforcement, vibration dampening, and surface finishing—in a unified construction. The molding process creates seamless integration of these layers, eliminating potential weak points while maintaining consistent thickness and curvature essential for ergonomic support. The painted finish employs multi-stage application techniques that create durable surfaces resistant to abrasion, impact, and environmental factors common in public spaces. This structural approach ensures that the chair maintains its form and function through years of intensive public use while providing the foundational stability necessary for the integrated comfort systems.

Surface Refinement: Tactile and Visual Excellence

The chair incorporates premium linen/wool fabric finishes that offer sophisticated tactile qualities while meeting rigorous performance requirements for public environments. These textile selections undergo specialized treatments that enhance durability without compromising their natural aesthetic appeal or breathability characteristics. Linen options provide exceptional moisture-wicking properties and natural texture variations that create visual depth, while wool alternatives offer inherent flame resistance and luxurious tactile warmth. Both fabric types employ advanced weaving techniques that increase tensile strength and resistance to pilling, ensuring long-term aesthetic preservation despite constant public use. The finishes are applied with precision tailoring that eliminates wrinkles or loose areas while creating seamless transitions between different chair components, resulting in professional appearance appropriate for formal institutional settings.

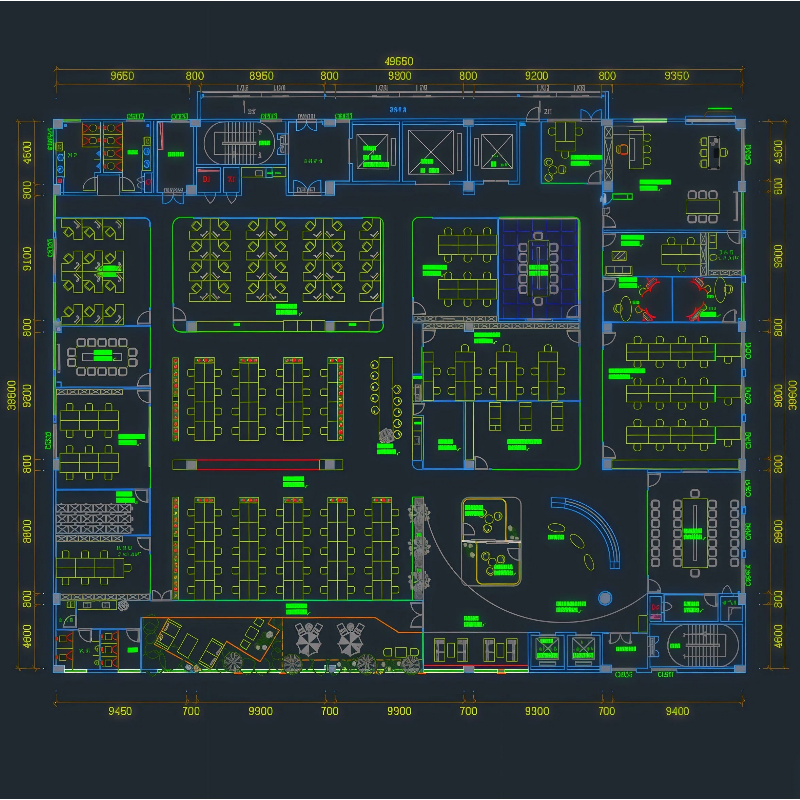

Framework Engineering: Precision Metallic Components

The chair's structural framework employs aluminum alloy armrest structures that provide exceptional strength-to-weight ratios while maintaining refined visual profiles. These alloy components undergo precision extrusion processes that create consistent cross-sectional geometries optimized for load distribution and user comfort. The aluminum receives specialized surface treatments including abrasive finishing that creates uniform matte textures with enhanced grip characteristics. Complementing these armrests are fixed aluminum feet with sandblasted gray finishes that provide stable foundation points while preventing floor surface damage through protective contact designs. These metallic elements create a cohesive visual language that balances industrial durability with architectural refinement, appropriate for spaces where furniture must withstand intensive use while maintaining professional appearance.

Aesthetic Detailing: Natural Material Accents

Adding warmth and visual contrast to the metallic framework are natural wood tone semi-open paint armrest covers that introduce organic materiality into the seating design. These components employ specialized finishing techniques where translucent coatings allow underlying wood grain patterns to remain partially visible, creating depth and character that evolves with viewing angles and lighting conditions. The semi-open painting process requires precise control of viscosity, application thickness, and drying conditions to achieve the ideal balance between surface protection and natural expression. These wooden elements undergo stabilization treatments that prevent warping or cracking in varying environmental conditions, ensuring consistent appearance and performance throughout auditorium spaces with different climate control characteristics.

Motion Control: Precision Response Mechanisms

At the core of the chair's functional intelligence lies its torsion spring + damping return mechanism that provides controlled, quiet movement during seating and standing transitions. This engineered system employs precisely calibrated torsion springs that store and release energy with consistent force profiles, paired with hydraulic damping elements that regulate motion speed to prevent sudden movements or loud operational sounds. The mechanism undergoes extensive cycle testing to ensure reliable performance through decades of frequent use, with lubrication systems that maintain smooth operation without requiring routine maintenance. This motion control engineering recognizes that in collective environments, seating movements should occur with minimal distraction, creating transitions that feel intuitive rather than mechanical while ensuring consistent performance across all seating positions within an auditorium.

Acoustic Considerations: Sound Management Integration

Beyond physical comfort, the chair incorporates subtle acoustic optimization features that contribute to overall auditory environment quality. Material selections and construction methods minimize sound generation during movement, while fabric choices provide sound absorption characteristics that reduce reverberation in enclosed spaces. The chair's structural design avoids hollow cavities that could amplify noise, instead employing dense materials that dampen vibration transmission. These acoustic considerations are particularly valuable in performance venues and lecture halls where clear sound transmission is essential, creating seating that contributes positively to the auditory experience rather than introducing distracting noise elements.

Durability Engineering: Public Environment Resilience

Every component demonstrates engineered durability specifically designed for the demands of public institutional environments. Materials undergo accelerated aging tests simulating years of intensive use, with particular attention to resistance against abrasion, impact, UV exposure, and cleaning chemicals. Connection points employ reinforced fastening systems that prevent loosening through vibration or frequent use, while all surfaces incorporate protective treatments that maintain appearance despite constant contact. This durability focus ensures that the chairs maintain their functional and aesthetic qualities through years of continuous service, representing long-term value for institutions requiring reliable public seating solutions.

Manufacturing Precision and Quality Assurance

Each chair originates from Guangdong manufacturing facilities where advanced production technologies ensure precision assembly and consistent quality. Computer-assisted fabrication maintains exacting tolerances particularly crucial for mechanism integration and ergonomic alignment. The painting and finishing processes occur in environmentally controlled chambers that ensure uniform application and optimal adhesion. Assembly incorporates specialized tooling that guarantees perfect alignment of all components, with particular attention to the integration of comfort systems and structural frameworks. Quality control protocols include cycle testing of mechanisms, structural load testing, and finish durability assessments under simulated public use conditions. This manufacturing commitment ensures consistent performance across all seating units within an installation.

Sustainable Public Seating Solutions

Embedded throughout the chair's design and production is a commitment to sustainable public furniture solutions. Material selections emphasize durability and longevity, reducing replacement frequency and associated resource consumption. Manufacturing processes optimize material usage and incorporate energy-efficient technologies. The modular design facilitates component replacement rather than complete unit disposal when damage occurs. Even packaging solutions minimize environmental impact while ensuring product protection during transportation. This holistic approach to sustainability aligns with growing environmental consciousness in public institutions, offering seating solutions that support both immediate functional needs and long-term ecological values.

Transformative Collective Experiences

Ultimately, the Cleader Auditorium Seating System represents more than public seating—it embodies architectural environmental design that understands how physical seating systems influence collective experiences in shared spaces. By integrating ergonomic comfort with durable construction, acoustic consideration with aesthetic refinement, and individual support with collective spatial efficiency, it creates seating environments that actively enhance rather than merely accommodate audience presence. The system recognizes that effective public seating must serve both universal human needs and specific institutional requirements, providing solutions that support diverse events while maintaining consistent quality and comfort. For institutions committed to creating spaces that foster engagement, support comfort through extended events, and enhance overall experience quality, this seating system offers intelligent solutions that translate understanding of collective environments into tangible design features, creating auditoriums where seating doesn't merely contain audiences but actively contributes to event success through thoughtful design that understands what people need to sit comfortably together and what spaces need to host collective experiences successfully.

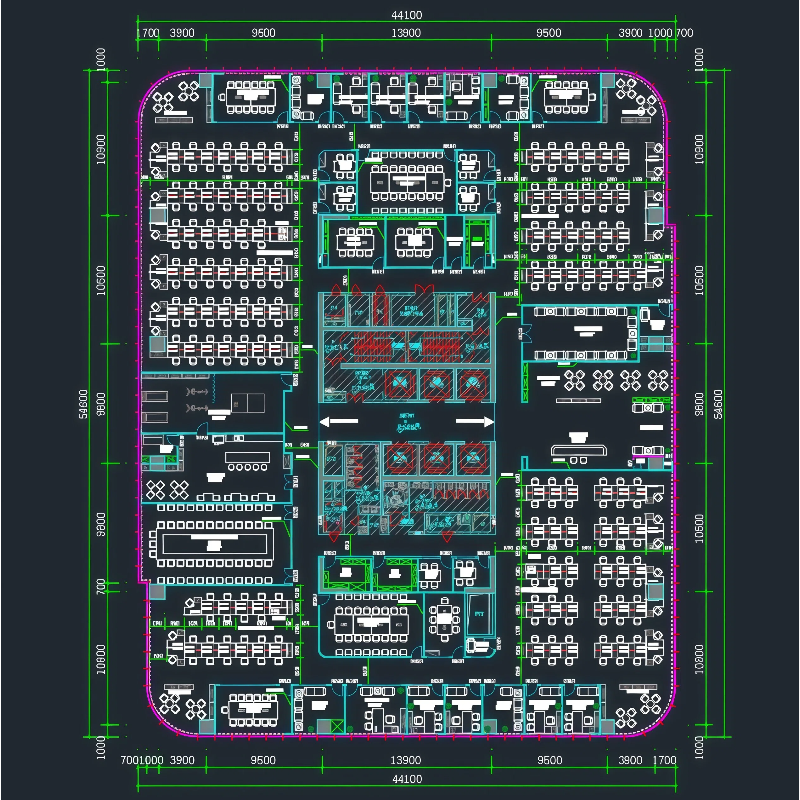

Specifications

| Place of Origin | Guangdong,China |

| Brand Name | Cleader |

| Sponge | Uses PU shaped sponge |

| Backrest outer panel | Uses high-quality multi-layer molded paint back panel |

| Fabric | Uses high-quality linen/wool fabric finish |

| Armrests | Use aluminum alloy armrests |

| Armrest cover | Uses natural wood color semi-open paint |

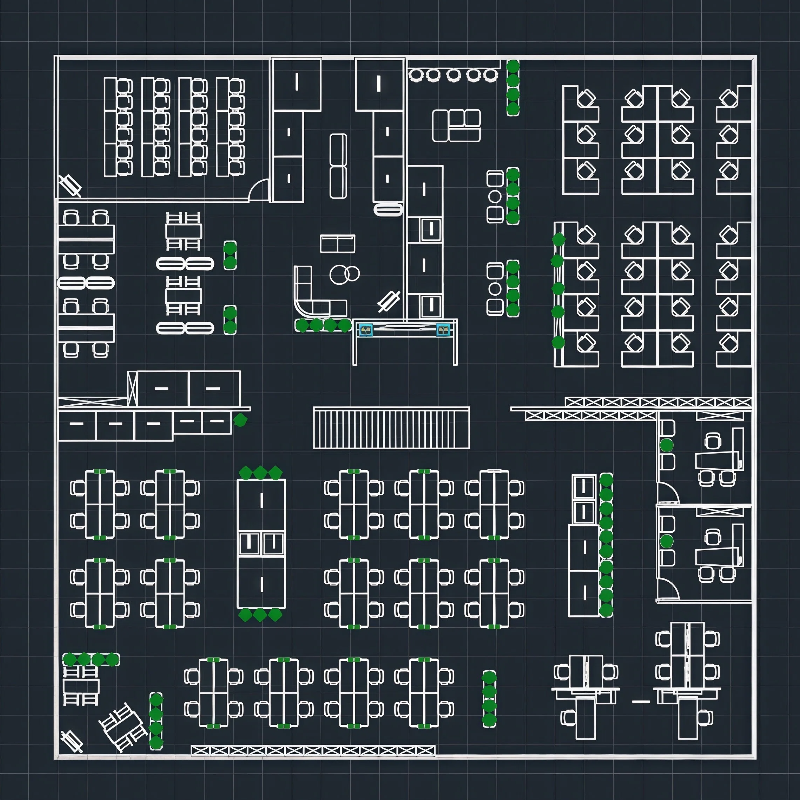

Applications

1. User Voice: Conference Center Operations Director

"This venue hosts over 200 events annually, from international summits to product launches. Cleaning efficiency is critical—we need to reconfigure the entire hall within 90 minutes."

Use Case: Multi-purpose conference centers, exhibition venues

Why Selected: Smooth molded back panel surfaces allow quick disinfection wiping; fixed installation ensures perfect alignment; wear-resistant fabric withstands high-frequency use

2. User Voice: Municipal Cultural Center Director

"The budget is limited but quality cannot be compromised. We need these chairs to remain in excellent condition for over 15 years, as repurchasing would require complex tender processes."

Use Case: Public cultural auditoriums, municipal assembly halls

Why Selected: Full aluminum alloy framework prevents rust issues; all external components are replaceable to extend service life; total cost of ownership is 40% lower than replacing cheap chairs every five years

Advantages

The Cleader Auditorium Chair delivers unparalleled value through a holistic design philosophy that prioritizes lifelong performance. Its multi-faceted strength originates from precision-engineered components: shape-retaining PU molded foam for consistent comfort, a monolithic molded back panel armored with a hard-wear paint coat, and a premium fabric blend chosen for its durability and sophistication. The lightweight yet incredibly sturdy aluminum alloy substructure guarantees unwavering stability. The sophisticated silent-return mechanism, featuring a precision damper, eliminates disruptive noise and reduces mechanical wear, addressing the key pain points of public seating. Beyond mere specifications, it offers complete peace of mind—combining robust construction, enduring comfort, and quiet operation into a cohesive, aesthetically pleasing package designed to perform flawbly for decades in demanding environments.

FAQ

Q1: What materials are used in it? Are they environmentally friendly?

A: All use high-quality materials that have received environmental certification.

Q2: Do you provide product samples? What about the cost?

A:Material samples can be provided. The shipping cost for the samples is at your own expense. For more requirements, please contact us.

Q3: What is the lead time for standard and customized orders?

A: Standard models ship within 25-35 business days.For more requirements, please contact us.

Q4: Can I customize sizes, colors, or finishes?

A: Support customization. For more requirements, please contact us..

Q5: Is an installation manual or tools provided?

A: We provide installation videos.

Q6: Do you provide bulk order discounts for corporate projects?

A: We can offer tiered discounted prices. For more details, please contact us.

Q7: What is the payment method?

A: We accept T/T. For more requirements, please contact us.