Sound Proof Office Phone Booth Acoustic Office Vocal Recording Pod

Handle: Stainless steel handle/Lockable handle

cold-rolled steel plates:0.8mm/1.2mm high-quality cold-rolled steel plates

Wheel: Steel universal wheel, free steering without pressure, beside the configuration of a steel foot cup to prevent the sound insulation room in static displacement

Lighting system: LED lighting with adjustable 3000-4000-6000K natural light color temperature

Cabin configuration: Multi-functional socket(Double five-hole socket +USB+Type-C)

Ventilation system: Dual circulation fresh air system with top intake and bottom exhaust. The temperature difference between the cabin and the external space environment does not exceed 2 degrees Celsius

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

Engineered for superior performance and user-centric operation, this solution begins with a fundamental commitment to efficiency via its modular design philosophy. This foundational principle is not merely a feature but a holistic strategy that addresses the core inefficiencies plaguing traditional space deployment. By deconstructing the monolithic concept of a room into a rationalized, pre-engineered system, it achieves a radical simplification of logistics, labor, and time. This approach ensures that every stage, from manufacturing and shipping to final assembly, is optimized for minimal waste and maximum predictability. The resulting product transcends being a physical object; it becomes a highly efficient process for acquiring a premium acoustic environment, perfectly aligned with the dynamic pace of modern business and institutional needs.

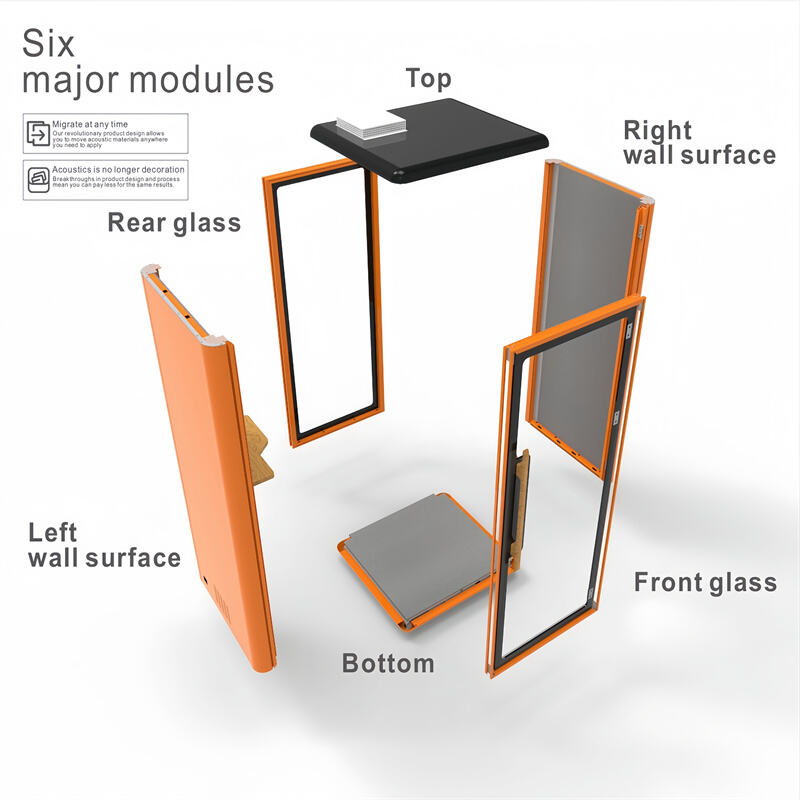

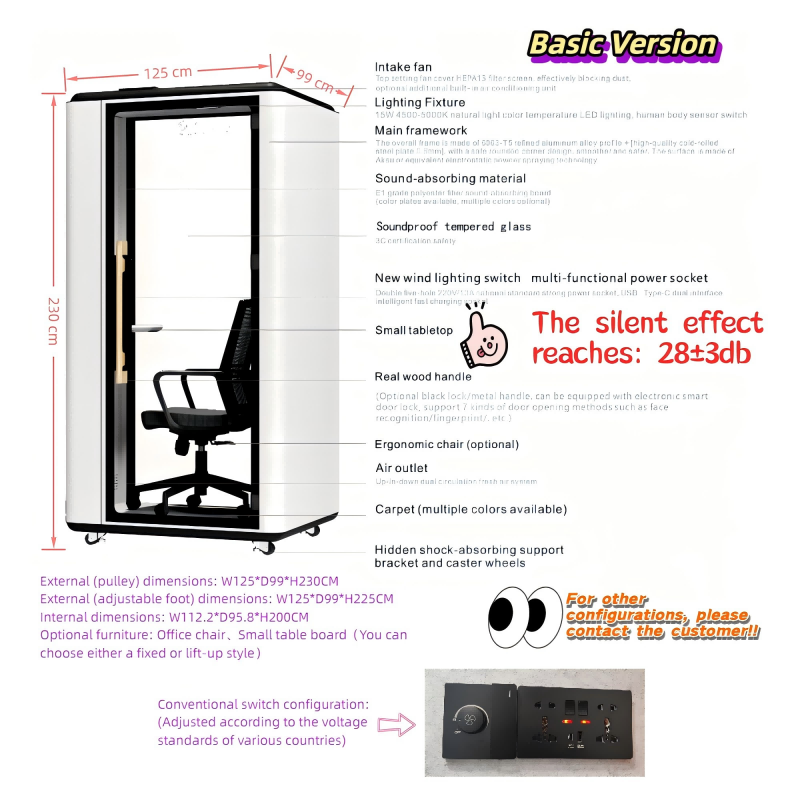

The streamlined, unified structural module system, consisting of only six key parts, transforms complex assembly into a straightforward 45-minute process, establishing a new benchmark for installation speed within the sector. This modular architecture represents a pinnacle of design for manufacture and assembly (DFMA). Each of the six key parts—typically encompassing the roof, floor, two side walls, the front door assembly, and the rear glass panel assembly—is a complete, pre-integrated sub-system. They are manufactured to micron-level tolerances in a controlled factory environment, where quality and precision can be guaranteed. This pre-integration includes pre-mounted seals, pre-installed electrical conduits, and embedded connection hardware. On-site, the process is reduced to its most logical sequence: positioning, aligning, and mechanically coupling these large modules. There is no cutting, drilling, or fabrication required. This elimination of skilled trades and complex tooling transforms complex assembly into a straightforward 45-minute process, drastically reducing labor costs, on-site errors, and operational downtime. This efficiency doesn't just save time; it redefines feasibility, making the deployment of private, focused spaces possible in scenarios where traditional construction would be prohibitively disruptive or slow, thereby establishing a new benchmark for installation speed within the sector.

The construction methodology prioritizes longevity and resilience, leveraging a hybrid material strategy. The product is built not for a product lifecycle, but for a building lifecycle. This endurance is engineered through intelligent material selection and combination. The primary load-bearing framework is crafted from 6063-T5 refined aluminum alloy, celebrated for its excellent strength-to-weight ratio. This specific alloy, after solution heat treatment and artificial aging (T5 temper), achieves an optimal balance of high tensile strength and low density. This means the structure is incredibly rigid and stable without being burdensomely heavy, a critical factor for modular handling and long-term dimensional stability. This aluminum framework is then synergistically combined with 0.8mm high-grade cold-rolled steel plates for added rigidity and impact resistance. The cold-rolling process increases the steel's yield strength and surface hardness. Strategically deployed, these steel plates reinforce critical junctions, mounting points, and the exterior skin, providing unparalleled resistance to denting, deformation, and point loads. This hybrid approach ensures the structure can withstand the rigors of transportation, assembly, and decades of daily use.

A high-performance surface treatment using top-tier electrostatic powder coating from suppliers like Akzonobel ensures exceptional corrosion resistance and long-term aesthetic preservation, verified by stringent adhesion testing. The durability of the metal is perfected by its finish. The electrostatic powder coating process involves applying a dry, free-flowing polymer powder that is electrostatically charged to adhere to the grounded metal substrate. It is then cured under heat to form a continuous, uniform film. Sourcing from top-tier suppliers like Akzonobel guarantees a formulation with superior UV inhibitors, pigments, and resins. This results in exceptional corrosion resistance, protecting against rust and oxidation. Its mechanical toughness resists chipping, scratching, and chemical abrasion from common cleaners, ensuring long-term aesthetic preservation. This performance is not assumed; it is verified by stringent adhesion testing such as cross-hatch and impact tests, which confirm the coating will not peel or delaminate over time, preserving the unit's like-new appearance.

The acoustic insulation package represents a sophisticated, science-driven approach to noise abatement. It is not a single material but a strategically assembled composite system. Acoustic engineering here follows the principles of multi-layer impedance mismatching and damping, addressing different sound transmission paths. This system starts with an inner liner of E1 class polyester fiber board for initial sound absorption. The E1 class certifies ultra-low formaldehyde emissions, making it safe for enclosed spaces. This porous layer effectively captures and dissipates mid-to-high frequency sound waves within the cabin, reducing reverberation and "bright" acoustic feedback. Deeper within, it fills the structural cavities with dense sound insulation cotton and felt to dampen vibrations. These materials, often a blend of natural and synthetic fibers, act as a decoupling mass, absorbing sound energy and converting it to minimal heat, while also breaking the mechanical transmission path between the inner and outer panels. The system then employs the external steel skin as a mass barrier. Following the Mass Law, this dense, airtight layer reflects a significant portion of incident sound energy, preventing its ingress. Finally, it completes the seal with EVA strips on every conceivable gap. Ethylene-Vinyl Acetate strips are compressed at all joints, creating a continuous airtight gasket that eliminates flanking transmission—the primary cause of acoustic failure in lesser designs. This holistic strategy achieves a consistent 28±3 dB noise reduction level, a quantifiable measure that translates to a drastic attenuation of external noise. Furthermore, it accomplishes this while utilizing core materials that are inherently safe, durable, and environmentally responsible—being waterproof, emission-free, flame-retardant, and chemically resistant.

The inclusion of 8mm 3C-certified tempered glass on the rear panel adds a critical layer of safety and supplementary sound damping. The glazing is a dual-purpose component. The 8mm thickness provides substantial mass. The 3C-certification is China's compulsory safety standard, guaranteeing the glass has been properly thermally tempered. This process increases its strength and, most importantly, ensures that if broken, it fractures into small, relatively harmless granular pieces rather than dangerous shards, adding a critical layer of safety. Acoustically, this thick, monolithic glass panel acts as a significant supplementary sound damping element, contributing to the overall Sound Transmission Class (STC) of the assembly.

The ventilation strategy is intelligently designed around occupant comfort, employing a dual-circulation fresh air mechanism that intakes air from the top and exhausts it from the bottom. Comfort in an enclosed space hinges on air quality and thermal stability. A simple exhaust fan would create negative pressure. This system is balanced: one fan intakes air from the top, drawing in fresh ambient air, while a second exhausts it from the bottom, removing warmer, stale air. This flow leverages natural convection, promoting a gentle, whole-space refresh. This creates a gentle, continuous air exchange without generating uncomfortable drafts or pressure imbalances. The balanced design maintains neutral internal pressure, which is crucial for the longevity of acoustic seals and user comfort. The integrated thermal design meticulously maintains an internal temperature within a mere 2°C of the surrounding space, preventing heat buildup from equipment, lighting, and occupancy.

Illumination is treated with equal care; the system utilizes 4500K natural spectrum LED lighting, a color temperature proven to align with human circadian rhythms and visual comfort, operable automatically for energy efficiency or manually for user preference. Light is engineered as a well-being tool. The 4500K natural spectrum provides a clean, neutral white that reduces the harsh blue-light peak associated with cooler temperatures, minimizing digital eye strain. This spectrum is proven to align with human circadian rhythms, supporting daytime alertness. For convenience and energy efficiency, it features automatic operation via occupancy sensor. For personalization, manual control allows users to adjust brightness to their preference, completing a deeply considered user experience.

Specifications

| Place of Origin | Guangdong,China |

| Brand Name | cleader |

| Model Number | CA-X002 |

| Product Dimensions | 1250W*990D*2300H |

| Number of fans | 1 |

| Shape | Rectangle |

| Board material | Medium-density fiberboard |

| Framework materials | High-strength aluminum profile |

| soundproof tempered glass | 8mm transparent 3C-certified safety and soundproof tempered glass/5+ (1.14pvd) +5mm transparent 3c certified safety, laminated soundproof tempered glass |

| Handle | Stainless steel handle/Lockable handle |

| cold-rolled steel plates | 0.8mm/1.2mm high-quality cold-rolled steel plates |

| Wheel | Steel universal wheel, free steering without pressure, beside the configuration of a steel foot cup to prevent the sound insulation room in static displacement |

| Lighting system | LED lighting with adjustable 3000-4000-6000K natural light color temperature |

| Cabin configuration | Multi-functional socket(Double five-hole socket +USB+Type-C) |

| Ventilation system | Dual circulation fresh air system with top intake and bottom exhaust. The temperature difference between the cabin and the external space environment does not exceed 2 degrees Celsius |

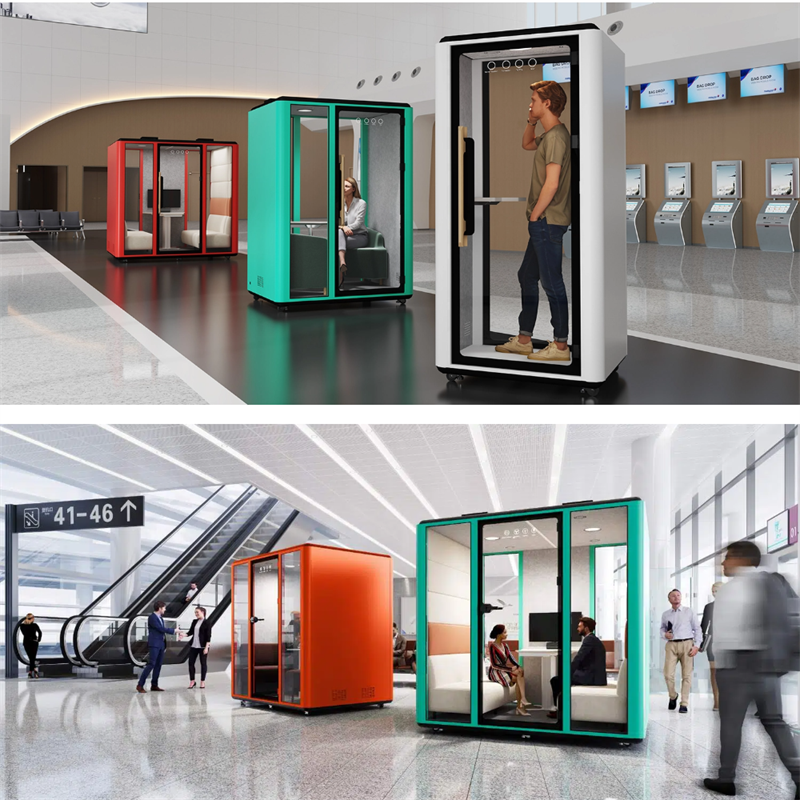

Applications

Advantages

Our solution delivers unmatched value through a holistic feature set designed for immediate and long-term benefits. Its modular architecture translates to a swift 45-minute setup, saving significant time and labor costs. The robust hybrid metal construction and premium finish promise years of reliable service with minimal upkeep. Occupants enjoy a profoundly quiet workspace, insulated by a 28 dB-rated system made from safe, non-toxic materials. The environment remains fresh and thermally stable, courtesy of an intelligent ventilation system that prevents drafts and temperature swings. The integration of 4500K health-spectrum lighting reduces eye strain, while the certified safety glass ensures security. This combination directly enhances productivity, well-being, and operational efficiency.

FAQ

Q1: What is the sound insulation rating of your phone booths?

A: Our silent cabin is equipped with a multi-layer sound insulation system, which can achieve a sound insulation effect of 28±3 and 32±3 decibels.Please refer to the product description for details.

Q2: How long does installation take?

A: Thanks to the modular design with only six main components, installation typically takes about 45 minutes on-site.We offer installation videos.

Q3: Do you offer different sizes for single, double, or multiple-person booths?

A: Yes, we offer various sizes of silent cabins, including single and double, and the size can be customized according to your needs. For more requirements, please contact us.

Q4: How is ventilation handled inside the booth?

A: Each booth features a dual-circulation fresh air system with top intake and bottom exhaust, maintaining a temperature difference of less than 2°C from the outside environment.

Q5: Can I add additional features like monitor mounts or extra power outlets?

A: Absolutely.For more requirements, please contact us.

Q6: What is the lead time for standard and customized orders?

A: Standard models ship within 20-25 business days.For more requirements, please contact us.

Q7: What is the payment method?

A: We accept T/T. For more requirements, please contact us.

Q8: Do you provide product samples? What about the cost?

A:Material samples can be provided. The shipping cost for the samples is at your own expense. For more requirements, please contact us.