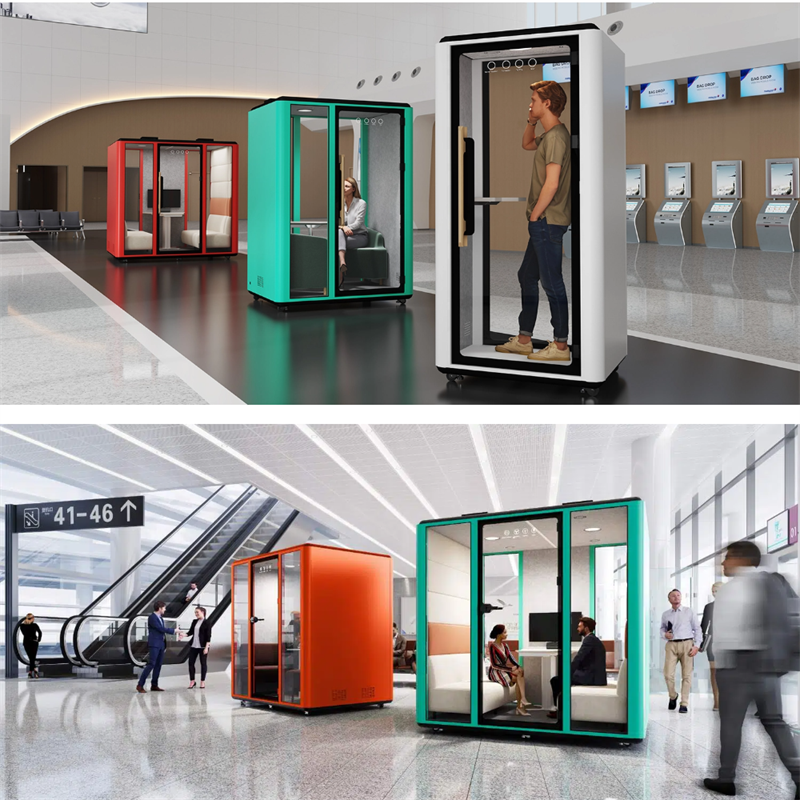

Modern easy-to-install mobile phone booths, soundproof private meeting pods

Handle: Stainless steel handle/Lockable handle

cold-rolled steel plates: 0.8mm/1.2mm high-quality cold-rolled steel plates

Wheel: Steel universal wheel, free steering without pressure, beside the configuration of a steel foot cup to prevent the sound insulation room in static displacement

Lighting system: LED lighting with adjustable 3000-4000-6000K natural light color temperature

Cabin configuration: Multi-functional socket(Double five-hole socket +USB+Type-C)

Ventilation system: Dual circulation fresh air system with top intake and bottom exhaust. The temperature difference between the cabin and the external space environment does not exceed 2 degrees Celsius

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

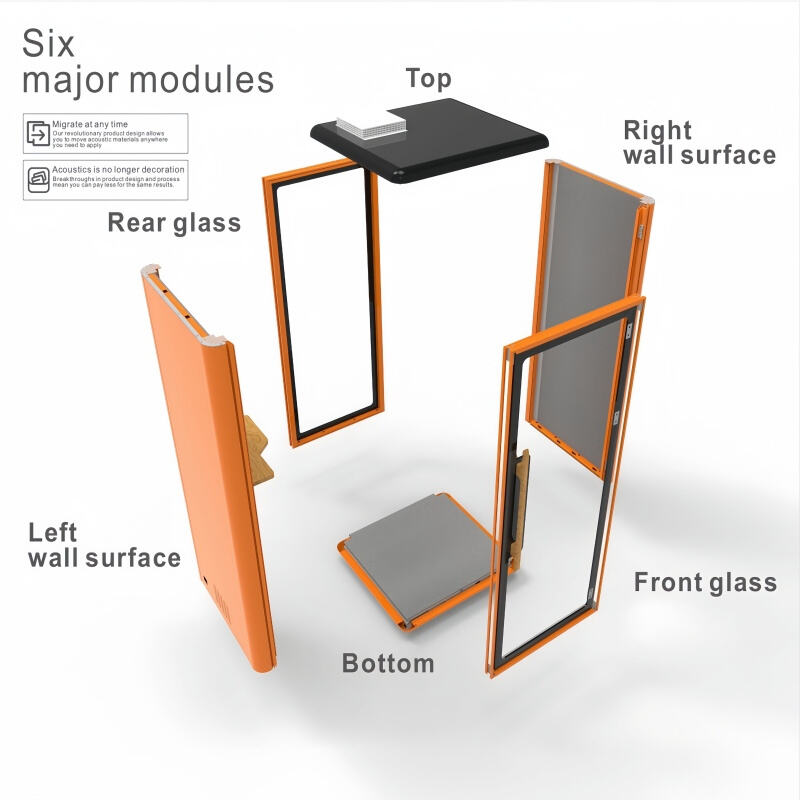

The Structural and Deployment System is the foundation, employing modularity and high-strength materials (6063-T5 Al alloy, 0.8mm steel) to enable rapid, 45-minute assembly and provide a durable chassis. This system fundamentally redefines the procurement and deployment of a high-performance acoustic environment. Its architecture is not merely assembled; it is engineered for integration. The principle of modularity is executed through a limited set of macro-components—typically no more than six major panels. Each panel is a complete, factory-finished assembly incorporating its segment of the structural frame, acoustic layers, interior finish, and pre-installed electrical pathways. This off-site integration ensures millimeter-perfect tolerances and eliminates the variability of on-site construction. The high-strength materials are deliberately paired: the 6063-T5 aluminum alloy provides the primary structural lattice, offering an exceptional strength-to-weight ratio and inherent corrosion resistance, which is critical for maintaining dimensional stability over time and across relocations. The 0.8mm steel sheets are strategically employed as exterior cladding and reinforcement at load-bearing junctions, adding crucial mass for acoustics and formidable resistance to impact. Together, this material synergy creates a chassis that is both lightweight for handling and immensely rigid when locked together. The connection mechanisms between these modules are designed for intuitive, tool-assisted coupling, transforming assembly into a rapid, predictable sequence rather than a skilled trade. The result is the enablement of a reliable, repeatable 45-minute assembly process. This speed is not an incidental benefit but a core design outcome, drastically reducing the labor cost, logistical complexity, and operational downtime associated with creating a dedicated space. The resulting durable chassis is not an end in itself; it is the essential, stable platform upon which all subsequent performance systems depend.

This chassis directly enables the performance of the Acoustic Dampening System, which is a multi-domain solution. It addresses airborne sound through mass (steel plates, glass), absorbs mid-frequency noise with the polyester fiber board, dampens structure-borne vibration with internal cotton/felt, and eliminates flanking transmission via hermetic EVA sealing—all with materials chosen for their environmental stability (waterproof, flame-retardant). The acoustic performance is a direct consequence of the stable platform provided by the chassis and a sophisticated, layered engineering strategy. It is a multi-domain solution because it attacks sound transmission on four distinct physical fronts. First, it confronts airborne sound through the application of mass. The law of mass dictates that a dense, limp barrier impedes sound transmission; this is provided by the steel plates of the chassis and the substantial mass of the glazing. Second, it manages mid-frequency noise, which is often the most distracting for speech, through absorption. The polyester fiber board lining the interior is a porous, open-cell material that converts sound wave energy into negligible heat through frictional losses within its matrix. Third, it controls structure-borne vibration, the energy that travels through the physical structure itself. This is mitigated by the internal cotton/felt layer, which acts as a decoupling and damping material, dissipating vibrational energy before it can re-radiate as sound inside the cabin. The fourth and most critical domain is the elimination of flanking transmission, the leakage of sound through the tiny gaps and seams inevitable in any assembly. This is solved by the hermetic EVA sealing. Ethylene-Vinyl Acetate (EVA) gaskets are compressed at every single joint and perimeter, creating a continuous, airtight seal that blocks this primary path of acoustic failure. The performance of this composite system is holistic, but its integrity is equally dependent on the environmental stability of its constituent materials. Their waterproof nature prevents degradation, mold, or loss of performance due to humidity. Their flame-retardant properties are a non-negotiable safety requirement, ensuring the materials do not become a fire hazard. This careful material selection guarantees that the acoustic performance is durable, safe, and consistent over the product's entire lifespan.

This quiet internal environment is then regulated by the Climate Management System. The dual-circulation fresh air system is precisely engineered to refresh air without disrupting the thermal and acoustic integrity of the space, using a top-to-bottom flow to minimize cross-drafts and maintain a negligible 2°C temperature differential. A perfectly quiet but stagnant or thermally unstable environment would be unusable for extended periods. The Climate Management System is the intelligent response to this challenge. Its core is the dual-circulation fresh air system. Unlike a simple exhaust fan, this system employs two matched, low-noise fans operating in concert: one introduces fresh, filtered air from the room, while a second exhausts an equal volume of stale air. This balance is precisely engineered to achieve air exchange without disrupting the thermal and acoustic integrity. Neutral pressure is maintained, preventing stress on the acoustic seals (which would create leaks) and avoiding the physical discomfort of pressure differentials. The airflow strategy employs a top-to-bottom flow. Fresh air is introduced near the ceiling, and stale air is extracted near the floor. This leverages natural convection—warm air rises—to promote gentle, whole-space mixing. This design minimizes cross-drafts, ensuring the occupant does not feel a direct, uncomfortable stream of air. Furthermore, this managed airflow, combined with the insulation inherent in the acoustic walls, allows the system to maintain a negligible 2°C temperature differential between the interior and the external room. This prevents the "greenhouse effect" of heat buildup from equipment, lighting, and the occupant's own metabolism, ensuring the acoustic sanctuary is also a thermally comfortable one.

Concurrently, the Visual Comfort System illuminates this controlled environment with 4500K natural light LEDs, a color temperature selected for its alignment with visual health standards, mitigating the strain associated with artificial lighting. The final sensory layer addresses the critical sense of sight. The Visual Comfort System completes the engineered microenvironment. It utilizes 4500K natural light LEDs. The 4500K correlated color temperature is a neutral white that closely mimics the spectral quality of daylight. This specific temperature is selected for its alignment with visual health standards because it reduces the intense blue light peak associated with cooler, more clinical lighting (often 6500K), which is linked to digital eye strain and circadian rhythm disruption. By providing a balanced, high-quality spectrum, the system is mitigating the strain associated with artificial lighting, thereby supporting prolonged visual tasks, reducing fatigue, and contributing to overall occupant well-being and sustained focus within the space.

These systems—structural, acoustic, climatic, and visual—are seamlessly housed together, with elements like the 3C-certified 8mm tempered glass serving dual roles in both the safety/acoustic and transparency systems. The premium Akzonobel-grade powder coating protects the entire integrated assembly. The product's ultimate efficacy lies in the seamless integration of its four core systems. They are not loosely bundled features but are co-engineered to reside within and enhance a single, unified enclosure. This integration is exemplified by components serving multiple masters. The 3C-certified 8mm tempered glass is a prime example. As part of the safety/acoustic system, its 3C certification guarantees it meets rigorous impact safety standards, breaking into harmless granules if shattered. Its 8mm mass also contributes significantly to sound damping. Simultaneously, it is the central component of the transparency system, providing a clear, undistorted visual connection to the outside world, which is psychologically important for reducing the sense of confinement. This multifunctionality is a hallmark of intelligent design. Finally, the entire integrated assembly—the sum of these systems—is shielded by a premium Akzonobel-grade powder coating. This is not a generic finish; it is a high-performance polymer layer applied electrostatically and cured into a hard, continuous film. It provides superior resistance to abrasion, chemicals, and UV radiation, ensuring the aesthetic and protective integrity of the complex assembly within, from its structural skeleton to its final surface, is preserved for the long term. This protective skin symbolizes the holistic safeguarding of the carefully engineered environment inside.

Specifications

| Place of Origin | Guangdong,China |

| Brand Name | cleader |

| Model Number | CA-X004 |

| Product Dimensions | 1950W*1282D*2300H |

| Number of fans | 2 |

| Shape | Rectangle |

| Board material | Medium-density fiberboard |

| Framework materials | High-strength aluminum profile |

| soundproof tempered glass | 8mm transparent 3C-certified safety and soundproof tempered glass/5+ (1.14pvd) +5mm transparent 3c certified safety, laminated soundproof tempered glass |

| Handle | Stainless steel handle/Lockable handle |

| cold-rolled steel plates | 0.8mm/1.2mm high-quality cold-rolled steel plates |

| Wheel | Steel universal wheel, free steering without pressure, beside the configuration of a steel foot cup to prevent the sound insulation room in static displacement |

| Lighting system | LED lighting with adjustable 3000-4000-6000K natural light color temperature |

| Cabin configuration | Multi-functional socket(Double five-hole socket +USB+Type-C) |

| Ventilation system | Dual circulation fresh air system with top intake and bottom exhaust. The temperature difference between the cabin and the external space environment does not exceed 2 degrees Celsius |

Applications

Advantages

Representing the pinnacle of engineered environments, this enclosure seamlessly integrates advanced technologies. Its elegantly simple modular design belies a sophisticated six-part system that assembles in a mere 45 minutes. The structure is a symphony of 6063-T5 aluminum and cold-rolled steel, cloaked in a faultless powder-coated finish. Within, a meticulously calibrated acoustic ecosystem achieves 28±3 dB of serene isolation, employing only certified, high-performance materials. A pane of 8mm 3C-certified glass offers clarity and quiet. An implicit climate is maintained by a self-balancing dual ventilation system, while illumination is rendered in a scientifically optimized 4500K spectrum. This is not merely a product, but a testament to holistic design intelligence.

FAQ

Q1: What is the sound insulation rating of your phone booths?

A: Our silent cabin is equipped with a multi-layer sound insulation system, which can achieve a sound insulation effect of 28±3 and 32±3 decibels.Please refer to the product description for details.

Q2: How long does installation take?

A: Thanks to the modular design with only six main components, installation typically takes about 45 minutes on-site.We offer installation videos.

Q3: Do you offer different sizes for single, double, or multiple-person booths?

A: Yes, we offer various sizes of silent cabins, including single and double, and the size can be customized according to your needs. For more requirements, please contact us.

Q4: How is ventilation handled inside the booth?

A: Each booth features a dual-circulation fresh air system with top intake and bottom exhaust, maintaining a temperature difference of less than 2°C from the outside environment.

Q5: Can I add additional features like monitor mounts or extra power outlets?

A: Absolutely.For more requirements, please contact us.

Q6: What is the lead time for standard and customized orders?

A: Standard models ship within 20-25 business days.For more requirements, please contact us.

Q7: What is the payment method?

A: We accept T/T. For more requirements, please contact us.

Q8: Do you provide product samples? What about the cost?

A:Material samples can be provided. The shipping cost for the samples is at your own expense. For more requirements, please contact us.