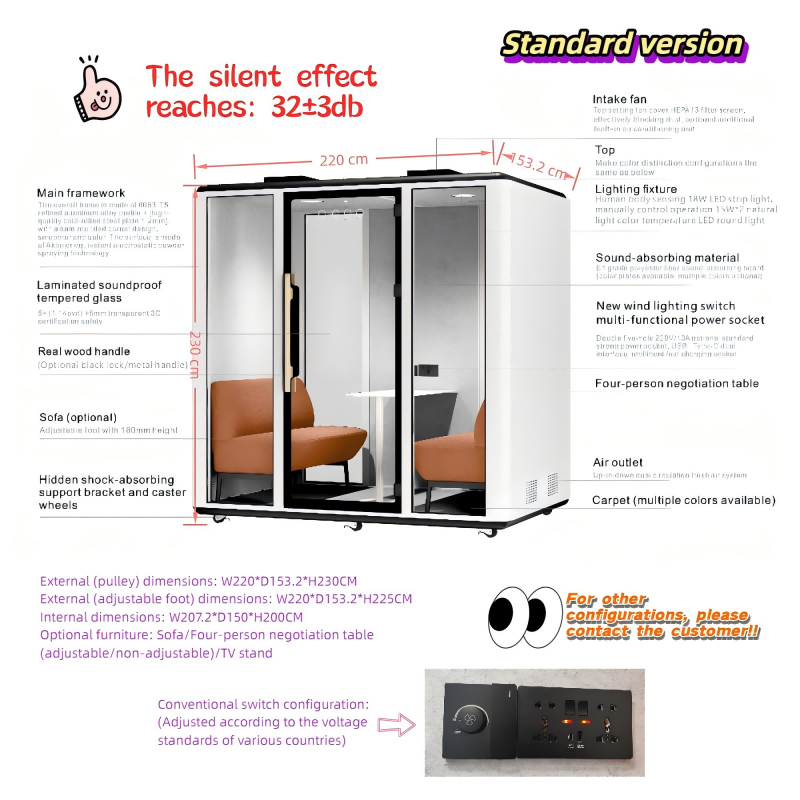

Modern Executive Privacy Meeting Pod Durable Aluminum Alloy Oblong Foldable

Handle: Stainless steel handle/Lockable handle

cold-rolled steel plates: 0.8mm/1.2mm high-quality cold-rolled steel plates

Wheel: Steel universal wheel, free steering without pressure, beside the configuration of a steel foot cup to prevent the sound insulation room in static displacement

Lighting system: LED lighting with adjustable 3000-4000-6000K natural light color temperature

Cabin configuration: Multi-functional socket(Double five-hole socket +USB+Type-C)

Ventilation system: Dual circulation fresh air system with top intake and bottom exhaust. The temperature difference between the cabin and the external space environment does not exceed 2 degrees Celsius

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

From an engineering perspective, this acoustic enclosure represents a holistic systems engineering achievement, demonstrating sophisticated integration of materials science, mechanical design, acoustical physics, and environmental control principles. It is conceived not as a collection of parts, but as a single, optimized performance envelope where every subsystem is co-engineered to achieve a set of rigorously defined operational objectives. The design philosophy is rooted in first principles, treating challenges such as sound transmission, thermal management, structural longevity, and user well-being as interrelated problems solved through a unified technical strategy. The result is a product where performance is predictable, reliable, and derived from quantifiable engineering choices rather than empirical assembly.

Structural & Mechanical Engineering: Precision, Integrity, and Deployment Efficiency

The foundation of the enclosure's performance lies in its structural system, which balances lightweight rigidity with exceptional build quality and unprecedented deployment speed.

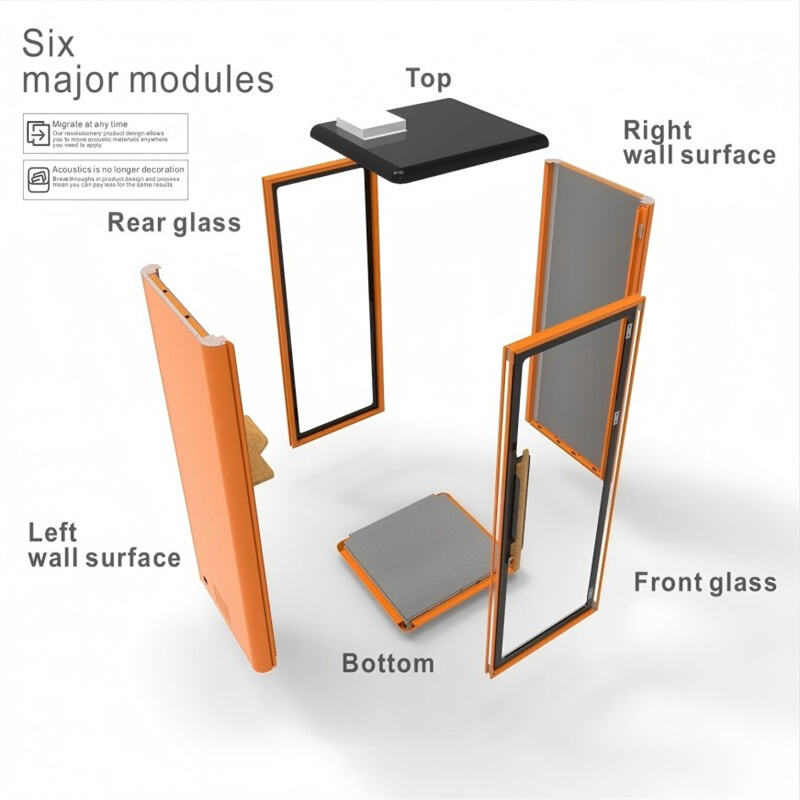

Modular Architectural Design: The modular architecture is a feat of design for manufacturing and assembly (DFMA). It employs precisely six precision-manufactured components, a number optimized to minimize logistical complexity, on-site handling, and potential assembly errors. Each component is a self-contained sub-assembly with integrated alignment features, wiring harnesses, and pre-installed seals. This systematic approach is what enables the remarkable 45-minute field assembly by a small team, drastically reducing installation cost and downtime.

Advanced Composite Framework: The load-bearing structure is a composite framework strategically combining 6063-T5 aluminum alloy profiles for the primary exoskeleton and 1.2mm cold-rolled steel plates at high-stress junctures and mounting points. The 6063-T5 aluminum, a heat-treatable alloy, provides an optimal strength-to-weight ratio, excellent corrosion resistance, and inherent dimensional stability critical for maintaining seal integrity. The 1.2mm cold-rolled steel adds localized, high-tensile strength and vibrational damping where needed. This hybrid approach maintains structural integrity while optimizing weight and material performance.

Surface Engineering and Durability: Long-term aesthetics and corrosion resistance are engineered through surface protection via electrostatic powder coating processes equivalent to Akzo standards. This involves a multi-stage pre-treatment (cleaning, phosphating) followed by the electrostatic application of a thermosetting polymer powder, cured into a continuous, durable film. The coating's adhesion properties are verified through standardized testing protocols such as cross-cut tape tests (ASTM D3359) and salt spray testing (ASTM B117), ensuring resistance to peeling, chipping, and environmental degradation.

Acoustical Engineering: A Physics-Based Multi-Layer Defense System

The core function of sound isolation is achieved not by mass alone, but through a meticulously sequenced strategy of impedance mismatching and damping.

Multi-Layer Strategy for Sound Transmission Reduction: The design implements a multi-layer strategy engineered to achieve 32±3 dB sound transmission reduction (a quantifiable Sound Transmission Class, STC, or similar rating). This performance is attained through the principle of sequential impedance mismatching, where each layer presents a different acoustic impedance to incident sound waves, causing destructive interference and significant energy loss at each boundary.

Layer-by-Layer Acoustical Composition:

Interior Porous Absorber (E1 Polyester Fiber): The innermost layer is a non-directional, porous absorber made of E1-grade polyester fiber. This material effectively converts acoustic energy within the cabin into negligible heat through frictional and viscous losses within its matrix, attenuating mid-to-high frequencies and reducing internal reverberation.

Cavity Damping Materials (Insulation Cotton/Felt): Within the wall cavity resides damping materials such as dense insulation cotton or felt. This layer serves multiple purposes: it acts as a decoupler between inner and outer panels (breaking mechanical contact), provides additional broadband absorption, and adds thermal insulation.

Exterior Mass Barrier (Steel Panel): The outer shell acts as the primary mass barrier, typically a steel panel. Mass Law principles dictate that this dense, limp layer reflects a significant portion of the remaining sound energy, its effectiveness increasing with both surface density and frequency.

Comprehensive Flanking Path Elimination (EVA Seals): Perhaps most critical is the comprehensive flanking path elimination achieved via continuous EVA (Ethylene-Vinyl Acetate) seals on all panel joints, door perimeters, and service penetrations. These elastomeric seals ensure an airtight assembly, preventing sound leakage, which is often the primary failure point in acoustic enclosures.

Materials Science and Compliance Engineering

Every material is specified not only for performance but for environmental, safety, and regulatory compliance.

Holistic Material Specifications: Key material specifications include:

Waterproofing: Inherent or treated resistance to moisture ingress.

Zero VOC Emissions: Adhesives, coatings, and composites are selected to meet stringent indoor air quality standards, emitting no harmful volatile organic compounds.

Flame Retardancy: Materials comply with UL94 standards or equivalent, defining the flammability classification of plastic materials.

Resistance to Chemical Exposure: Surfaces are resistant to common cleaning agents and incidental chemical spills.

Integrated Subsystem Engineering

Performance is further assured through the engineered integration of critical subsystems.

Glazing System Engineering: The glazing system utilizes a 5+(1.14pvd)+5mm laminated construction. This denotes two panes of 5mm glass bonded with a 1.14mm thick polyvinyl butyral (PVB) interlayer. This construction holds 3C certification for safety. Acoustically, the PVB layer provides significant damping, and the combined mass and decoupling effect of the two glass panes contribute to the overall acoustic mass and performance, often outperforming monolithic glass of equivalent total thickness.

HVAC Engineering: The HVAC engineering solution employs a balanced dual-path ventilation system. Two independently controlled, low-noise fans manage inbound and outbound airflow to maintain neutral pressure differentials (preventing door seal strain and air leakage). The system design, including duct geometry and insulation, along with the enclosure's thermal breaks, works to limit thermal transfer to ≤2°C through optimized airflow patterns that minimize stratification and hotspots.

Lighting and Control Engineering: Lighting engineering implements 4500K correlated color temperature LEDs. This CCT provides a neutral white light conducive to focus. The LEDs are selected for their appropriate spectral characteristics for visual ergonomics, including high Color Rendering Index (CRI >90) and flicker-free drivers to reduce eye strain. This is complemented by intelligent control systems allowing for dimming, scheduling, and integration with occupancy sensors.

Conclusion: Verifiable Performance through Systems Engineering

This comprehensive engineering approach—spanning structural design, acoustical physics, material compliance, and subsystem integration—ensures consistent, verifiable performance across all operational parameters. Each specification, from the 32±3 dB rating and 45-minute assembly to the ≤2°C thermal stability and 3C-certified glazing, is a direct output of a calculated design decision. The enclosure is therefore not merely a product but a predictable and reliable performance asset, its capabilities fully characterized and grounded in demonstrable engineering principles.

Specifications

| Place of Origin | Guangdong,China |

| Brand Name | cleader |

| Model Number | CA-X005P |

| Product Dimensions | 2200W*1532D*2300H |

| Number of fans | 4 |

| Shape | Rectangle |

| Board material | Medium-density fiberboard |

| Framework materials | High-strength aluminum profile |

| soundproof tempered glass | 8mm transparent 3C-certified safety and soundproof tempered glass/5+ (1.14pvd) +5mm transparent 3c certified safety, laminated soundproof tempered glass |

| Handle | Stainless steel handle/Lockable handle |

| cold-rolled steel plates | 0.8mm/1.2mm high-quality cold-rolled steel plates |

| Wheel | Steel universal wheel, free steering without pressure, beside the configuration of a steel foot cup to prevent the sound insulation room in static displacement |

| Lighting system | LED lighting with adjustable 3000-4000-6000K natural light color temperature |

| Cabin configuration | Multi-functional socket(Double five-hole socket +USB+Type-C) |

| Ventilation system | Dual circulation fresh air system with top intake and bottom exhaust. The temperature difference between the cabin and the external space environment does not exceed 2 degrees Celsius |

Applications

Advantages

This product outperforms standard solutions comprehensively: it installs in 45 minutes, not hours; uses a stronger aluminum-steel hybrid frame; delivers true 32 dB acoustic isolation with safe materials; features safer laminated glass; maintains ≤2°C temperature stability with balanced air flow; and provides healthier 4500K lighting.

FAQ

Q1: What is the sound insulation rating of your phone booths?

A: Our silent cabin is equipped with a multi-layer sound insulation system, which can achieve a sound insulation effect of 28±3 and 32±3 decibels.Please refer to the product description for details.

Q2: How long does installation take?

A: Thanks to the modular design with only six main components, installation typically takes about 45 minutes on-site.We offer installation videos.

Q3: Do you offer different sizes for single, double, or multiple-person booths?

A: Yes, we offer various sizes of silent cabins, including single and double, and the size can be customized according to your needs. For more requirements, please contact us.

Q4: How is ventilation handled inside the booth?

A: Each booth features a dual-circulation fresh air system with top intake and bottom exhaust, maintaining a temperature difference of less than 2°C from the outside environment.

Q5: Can I add additional features like monitor mounts or extra power outlets?

A: Absolutely.For more requirements, please contact us.

Q6: What is the lead time for standard and customized orders?

A: Standard models ship within 20-25 business days.For more requirements, please contact us.

Q7: What is the payment method?

A: We accept T/T. For more requirements, please contact us.

Q8: Do you provide product samples? What about the cost?

A:Material samples can be provided. The shipping cost for the samples is at your own expense. For more requirements, please contact us.