Modern soundproof steel frame office working space furniture for phone booth

Handle: Stainless steel handle/Lockable handle

cold-rolled steel plates: 0.8mm/1.2mm high-quality cold-rolled steel plates

Wheel: Steel universal wheel, free steering without pressure, beside the configuration of a steel foot cup to prevent the sound insulation room in static displacement

Lighting system: LED lighting with adjustable 3000-4000-6000K natural light color temperature

Cabin configuration: Multi-functional socket(Double five-hole socket +USB+Type-C)

Ventilation system: Dual circulation fresh air system with top intake and bottom exhaust. The temperature difference between the cabin and the external space environment does not exceed 2 degrees Celsius

- Description

- Specifications

- Applications

- Advantages

- FAQ

- Recommended Products

Description

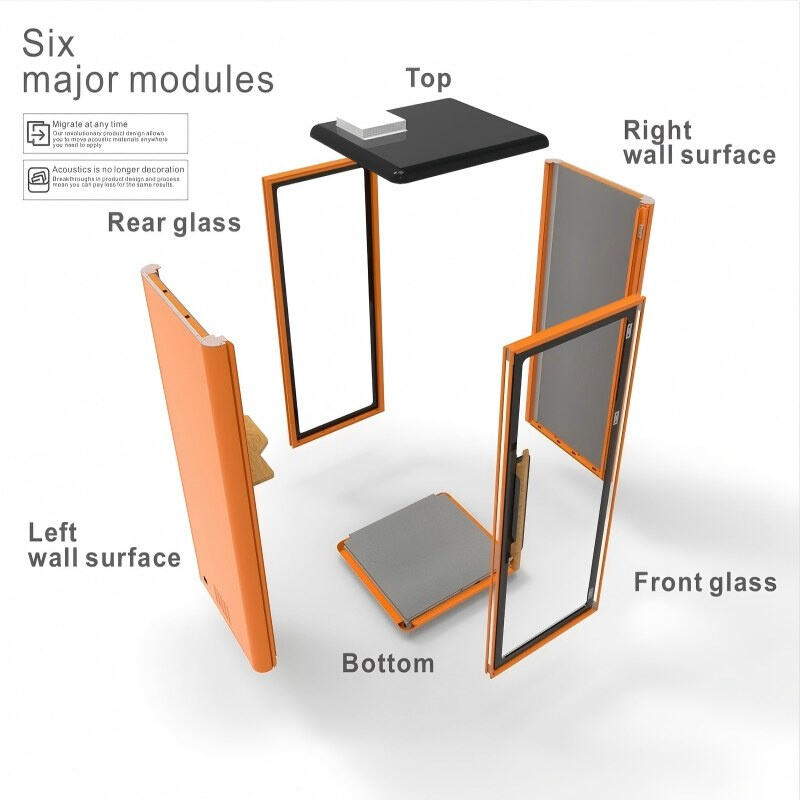

This high-performance unit features a modular design comprising six core components (top, bottom, glass door, and side walls), enabling rapid installation within 45 minutes for industry-leading efficiency. The foundation of the unit's value proposition is its engineered deployability. The modular design is not merely a convenience but a systematic approach to eliminating traditional construction bottlenecks. By condensing the entire structure into six core components—specifically, the top, bottom, glass door, and side walls—the system achieves an unprecedented reduction in on-site complexity. Each of these components is a fully integrated, pre-finished module manufactured under controlled factory conditions. This pre-integration includes all necessary structural elements, internal acoustic layers, pre-mounted seals, and wiring conduits. The on-site process is thereby transformed from a skilled construction task into a straightforward, sequential assembly of these macro-modules. Using intuitive connection systems, a small team can reliably complete the entire build process, achieving rapid installation within 45 minutes. This benchmark establishes industry-leading efficiency, directly translating to minimized labor costs, negligible operational disruption, and an exceptionally fast time-to-utility, allowing the asset to generate value almost immediately upon delivery.

The structural frame is constructed from 6063-T5 precision aluminum alloy profiles integrated with 1.2mm high-quality cold-rolled steel plates, finished with an Akzo-grade electrostatic powder coating that meets national standard adhesion tests. The unit's durability and stability are rooted in a hybrid material strategy. The primary load-bearing skeleton is formed from 6063-T5 precision aluminum alloy profiles. The "T5" designation indicates a specific heat treatment that optimizes the alloy's strength and dimensional stability, making it ideal for a rigid, lightweight framework that resists warping and corrosion. This aluminum structure is integrated with 1.2mm high-quality cold-rolled steel plates. The cold-rolling process enhances the steel's surface hardness and tensile strength. These steel plates serve as the exterior armor and provide crucial reinforcement at structural junctions, adding significant mass for acoustic performance and exceptional resistance to impact. The entire metal assembly is protected by a finish of Akzo-grade electrostatic powder coating. This high-quality coating process involves applying a dry polymer powder electrostatically, which is then thermally cured into a tough, uniform film. The performance of this finish is rigorously validated, as it meets nationalstandard adhesion tests (such as the cross-cut test), ensuring superior resistance to chipping, scratching, and environmental degradation for long-term durability and aesthetic preservation.

Acoustic performance is achieved through a multi-layer system: an interior E1-grade polyester fiber sound-absorbing board, cavity-filled sound insulation cotton and felt, an exterior sprayed steel panel, and EVA sealing strips in all gaps, delivering 32±3 dB sound insulation with waterproof, zero-emission, flame-retardant, and corrosion-resistant properties. The core function of the unit is realized via a sophisticated, physics-based acoustic engineering approach. This multi-layer system addresses the different mechanisms of sound transmission. The innermost layer is an interior E1-grade polyester fiber sound-absorbing board. The E1 grade certifies ultra-low formaldehyde emissions, ensuring healthy indoor air quality. This board effectively absorbs mid-to-high-frequency sound waves, reducing internal reverberation. Behind this layer, the structural cavity is cavity-filled with dense sound insulation cotton and felt. These materials provide broadband sound absorption and, critically, act as a damping mass to dissipate vibrational energy (structure-borne noise). The primary airborne sound barrier is the exterior sprayed steel panel—the same cold-rolled steel plate from the structure, which acts as a massive, limp layer to reflect sound energy. The integrity of this composite wall is sealed by EVA sealing strips in all gaps. These Ethylene-Vinyl Acetate strips are compressed at every joint and perimeter, creating a hermetic seal that eliminates sound leakage through flanking paths. Together, this system is responsible for delivering 32±3 dB sound insulation, a quantifiable performance metric indicating high-level noise reduction. All core acoustic materials are further engineered to possess waterproof, zero-emission, flame-retardant, and corrosion-resistant properties, ensuring the performance is durable, safe, and environmentally responsible.

Standard glazing consists of 5+(1.14pvd)+5mm laminated, 3C-certified safety and soundproof tempered glass. The transparent element is a high-performance component. The standard glazing is specified as 5+(1.14pvd)+5mm laminated... tempered glass. This denotes a laminated construction: two 5mm panes of glass are permanently bonded to a 1.14mm thick polyvinyl butyral (PVB) interlayer. This glass is tempered for strength and is 3C-certified, meeting China's compulsory safety standards. The lamination provides safety, as the PVB layer holds the glass together if shattered. The combination of the two glass masses and the damping PVB interlayer also contributes significantly to soundproof performance, enhancing the overall acoustic isolation of the assembly.

Ventilation is handled by a dual-circulation fresh air system (top intake, bottom exhaust) that maintains neutral internal pressure and limits temperature differentials to ≤2°C. Maintaining a comfortable and healthy microenvironment is critical. The solution is a ventilation system based on dual-circulation. It uses two balanced fans to manage airflow: one draws fresh air in from the top, while another exhausts stale air from the bottom. This top-to-bottom flow promotes natural convection and even air exchange. The balanced design is essential to maintain neutral internal pressure, preventing the discomfort and acoustic seal compromise caused by positive or negative pressure. Through this managed ventilation and the unit's insulation, the system effectively limits temperature differentials to ≤2°C compared to the external environment, preventing heat buildup and ensuring consistent thermal comfort.

The lighting system offers auto-sensing or manual control, utilizing 4500K natural-light LEDs compliant with visual health standards. The visual environment is optimized for user well-being and convenience. The lighting system provides flexible auto-sensing (typically via motion detection) for effortless, energy-efficient operation, or manual control for personalized adjustment. It utilizes 4500K natural-light LEDs. This specific color temperature provides a neutral white light spectrum that reduces the harsh blue light associated with eye strain. These LEDs are compliant with visual health standards, ensuring flicker-free operation and spectral qualities that support visual comfort during prolonged use, thereby completing the ergonomic design of the interior space.

Specifications

| Place of Origin | Guangdong,China |

| Brand Name | cleader |

| Model Number | CA-X001P |

| Product Dimensions | 1075W*990D*2300H |

| Number of fans | 1 |

| Shape | Rectangle |

| Board material | Medium-density fiberboard |

| Framework materials | High-strength aluminum profile |

| soundproof tempered glass | 8mm transparent 3C-certified safety and soundproof tempered glass/5+ (1.14pvd) +5mm transparent 3c certified safety, laminated soundproof tempered glass |

| Handle | Stainless steel handle/Lockable handle |

| cold-rolled steel plates | 0.8mm/1.2mm high-quality cold-rolled steel plates |

| Wheel | Steel universal wheel, free steering without pressure, beside the configuration of a steel foot cup to prevent the sound insulation room in static displacement |

| Lighting system | LED lighting with adjustable 3000-4000-6000K natural light color temperature |

| Cabin configuration | Multi-functional socket(Double five-hole socket +USB+Type-C) |

| Ventilation system | Dual circulation fresh air system with top intake and bottom exhaust. The temperature difference between the cabin and the external space environment does not exceed 2 degrees Celsius |

Applications

Advantages

This high-performance enclosure is defined by its rapid 45-minute modular assembly from six key components. Its robust structure combines 6063-T5 aluminum profiles with 1.2mm cold-rolled steel, finished with a durable Akzo-grade powder coating. A multi-layer acoustic system achieves 32±3 dB noise reduction, utilizing safe, waterproof, and flame-retardant materials. It features 5+(1.14pvd)+5mm 3C-certified laminated safety glass, a dual-circulation fresh air system that maintains neutral pressure and ≤2°C temperature variance, and a 4500K natural light LED system for visual comfort.

FAQ

Q1: What is the sound insulation rating of your phone booths?

A: Our silent cabin is equipped with a multi-layer sound insulation system, which can achieve a sound insulation effect of 28±3 and 32±3 decibels.Please refer to the product description for details.

Q2: How long does installation take?

A: Thanks to the modular design with only six main components, installation typically takes about 45 minutes on-site.We offer installation videos.

Q3: Do you offer different sizes for single, double, or multiple-person booths?

A: Yes, we offer various sizes of silent cabins, including single and double, and the size can be customized according to your needs. For more requirements, please contact us.

Q4: How is ventilation handled inside the booth?

A: Each booth features a dual-circulation fresh air system with top intake and bottom exhaust, maintaining a temperature difference of less than 2°C from the outside environment.

Q5: Can I add additional features like monitor mounts or extra power outlets?

A: Absolutely.For more requirements, please contact us.

Q6: What is the lead time for standard and customized orders?

A: Standard models ship within 20-25 business days.For more requirements, please contact us.

Q7: What is the payment method?

A: We accept T/T. For more requirements, please contact us.

Q8: Do you provide product samples? What about the cost?

A:Material samples can be provided. The shipping cost for the samples is at your own expense. For more requirements, please contact us.